O

Old Mod

Having been fortunate enough to work alongside @GaryTheTiler and

@Ray TT @ Porcel-Thin recently on a couple of projects it gave me a little hands on experience before I tackled my own bathroom refit for a client. This turned out to be invaluable!

The original ensuite was only 2yrs old and part of a massive remodelling of their property.

Long story kinda short. (For me! ) the floor had failed and the client just wanted whole room ripping out!

) the floor had failed and the client just wanted whole room ripping out!

This is what they wanted ripping out!

Basically the floor was a disaster waiting to happen.

They had placed OSB OVER joists and fixed.

Then placed 2x1 batons on OSB and put wet UFH trays between them.

Then GLUED ply on top. (Which de- bonded)

Then attempted to glue Ditra with AF200, which didn't work, so was effectively loose laid!

In fact the whole floor from the OSB up was effectively loose laid!

Anyway, after determining the position of the wet UFH pipes I screwed through the ply, 2x1, and batons into the joists.

No UFH piped were hurt in the making good of this floor!

Then I fixed 12mm Hardie on top! Screwing trough all layers where I could and into the ply elsewhere!

Yes the client was aware that this would reduce the effectiveness of the heating but felt it was a small price to pay fora solid floor!

This mess also left them with a split shower tray because although the times were meant to support the leading edge of the tray. They didn't. There just wasn't enough room for the trav to go under. So the tray was flexing which caused it to crack.

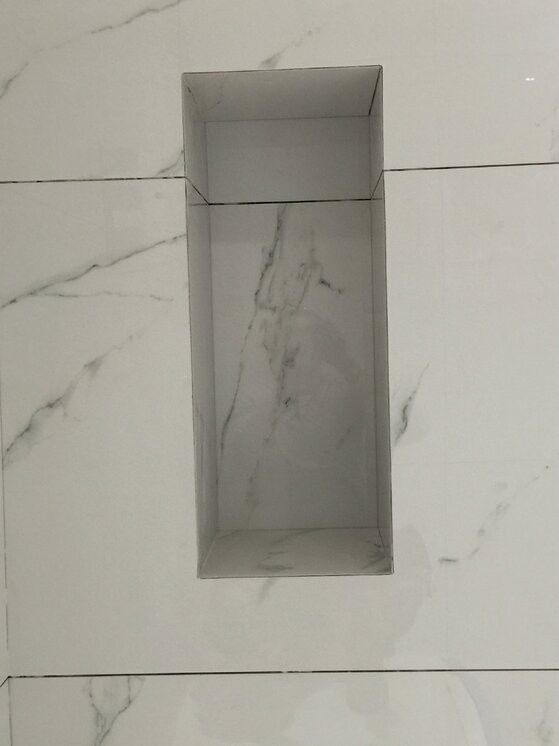

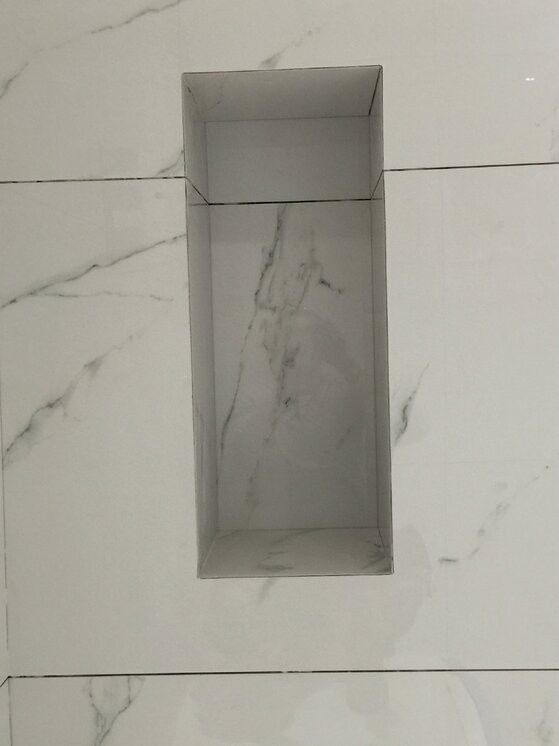

So remedials out of the way I began to transform their bathroom in to this!

@Ray TT @ Porcel-Thin recently on a couple of projects it gave me a little hands on experience before I tackled my own bathroom refit for a client. This turned out to be invaluable!

The original ensuite was only 2yrs old and part of a massive remodelling of their property.

Long story kinda short. (For me!

This is what they wanted ripping out!

Basically the floor was a disaster waiting to happen.

They had placed OSB OVER joists and fixed.

Then placed 2x1 batons on OSB and put wet UFH trays between them.

Then GLUED ply on top. (Which de- bonded)

Then attempted to glue Ditra with AF200, which didn't work, so was effectively loose laid!

In fact the whole floor from the OSB up was effectively loose laid!

Anyway, after determining the position of the wet UFH pipes I screwed through the ply, 2x1, and batons into the joists.

No UFH piped were hurt in the making good of this floor!

Then I fixed 12mm Hardie on top! Screwing trough all layers where I could and into the ply elsewhere!

Yes the client was aware that this would reduce the effectiveness of the heating but felt it was a small price to pay fora solid floor!

This mess also left them with a split shower tray because although the times were meant to support the leading edge of the tray. They didn't. There just wasn't enough room for the trav to go under. So the tray was flexing which caused it to crack.

So remedials out of the way I began to transform their bathroom in to this!