R

rainsco

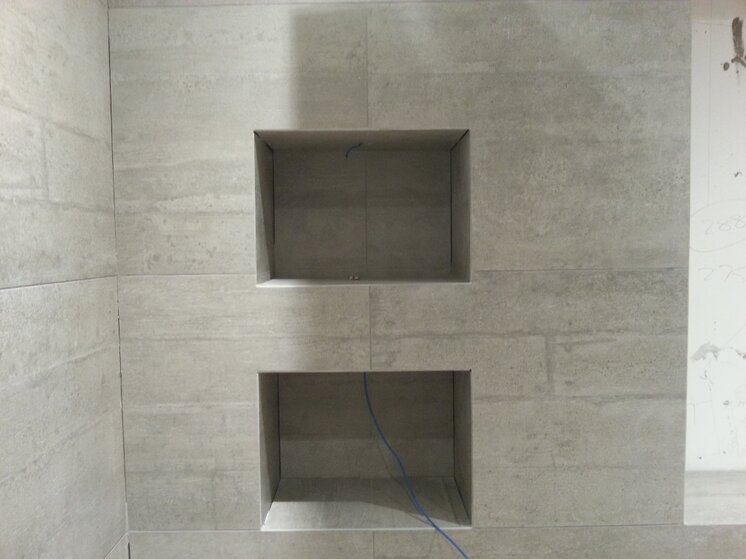

tray is customers choice. this customer lady has totaly fear of patina and dirt. so i groat the joins with epoxy in beige.

mitres are glued with akepox 2030. i mixed the color with fitting akemi color tubes. i tested integra which is available in 1000 colours but i go for epoxy because of diffrent causes.

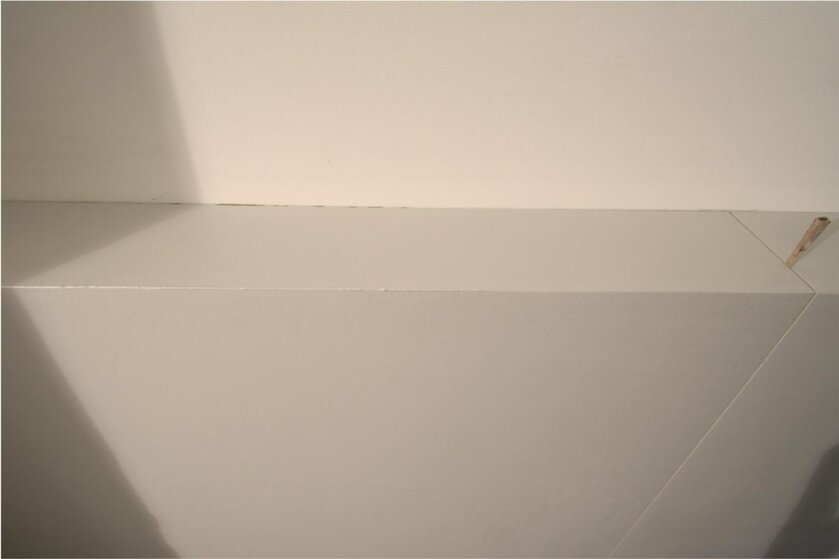

i do a lot of jobs now with glued mitres.. its cool on stairs:

mitres are glued with akepox 2030. i mixed the color with fitting akemi color tubes. i tested integra which is available in 1000 colours but i go for epoxy because of diffrent causes.

i do a lot of jobs now with glued mitres.. its cool on stairs: