D

Deleted member 51481

Hello All, I doubt anyone remembers me on here but I received a lot of helpful advice on an internal project so have returned.

I've now taken on a lockdown project which I'm part way through preparing the substrate for a large porcelain patio that I'm intending on laying myself - yikes. WIP pics attached. Some of the advice from last time was not to take on the internal project so I found a really good tiler who did a fantastic job which was a god send as I would not have met the critical Xmas deadline.

This time round there are different circumstances, minimal budget for materials only, no deadlines due to lockdown and as this job is external, any deviations would be acceptable unlike indoors within a new kitchen extension.

Having taken some advice off here in the past I have opted for the Porcelquick adped system which is basically a series of pedestals that is built up to the required height using a mix of sharp sand & cement and plastic rings. Once the pedestals have been created the tiles should be fixed using a C2 tiling adhesive.

I should also mention I'm using large format 800x400x20mm tiles and I'm not 100% sure on the best way to cut these tiles. I have a large Stihl disc cutter but I'm worried I won't achieve a straight line and I also have a new wet cutter from toolstation (QEP Diamond Wheel Wet Tile Cutter 450W - cutting depth is 23mm) with accompanying porcelain wheel blade which is unused and would prefer to return it for a refund its not deemed suitable.

Support at BAL has recommended the right products to use as follows:

Apply a priming coat of BAL Bond SBR (Diluted 4 parts water to 1 part BAL Bond SBR by volume).

BAL Pourable One tile adhesive which may be applied in bed thicknesses from 3mm to 25mm.

I would welcome any non-partisan advise on the above products and any alternatives too.

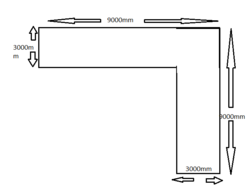

They've also mentioned I should install movement joints at 3m intervals but having scanned the net I'm struggling to work out what these are and exactly how to install, thickness, materials etc so any pointers would be really appreciated.

I appreciate this topic might not fit on this forum but unsure where else to go and everyone was super helpful with my internal project at end of 2018.

I've now taken on a lockdown project which I'm part way through preparing the substrate for a large porcelain patio that I'm intending on laying myself - yikes. WIP pics attached. Some of the advice from last time was not to take on the internal project so I found a really good tiler who did a fantastic job which was a god send as I would not have met the critical Xmas deadline.

This time round there are different circumstances, minimal budget for materials only, no deadlines due to lockdown and as this job is external, any deviations would be acceptable unlike indoors within a new kitchen extension.

Having taken some advice off here in the past I have opted for the Porcelquick adped system which is basically a series of pedestals that is built up to the required height using a mix of sharp sand & cement and plastic rings. Once the pedestals have been created the tiles should be fixed using a C2 tiling adhesive.

I should also mention I'm using large format 800x400x20mm tiles and I'm not 100% sure on the best way to cut these tiles. I have a large Stihl disc cutter but I'm worried I won't achieve a straight line and I also have a new wet cutter from toolstation (QEP Diamond Wheel Wet Tile Cutter 450W - cutting depth is 23mm) with accompanying porcelain wheel blade which is unused and would prefer to return it for a refund its not deemed suitable.

Support at BAL has recommended the right products to use as follows:

Apply a priming coat of BAL Bond SBR (Diluted 4 parts water to 1 part BAL Bond SBR by volume).

BAL Pourable One tile adhesive which may be applied in bed thicknesses from 3mm to 25mm.

I would welcome any non-partisan advise on the above products and any alternatives too.

They've also mentioned I should install movement joints at 3m intervals but having scanned the net I'm struggling to work out what these are and exactly how to install, thickness, materials etc so any pointers would be really appreciated.

I appreciate this topic might not fit on this forum but unsure where else to go and everyone was super helpful with my internal project at end of 2018.

Attachments

Last edited by a moderator: