Evening all,

got a job to start next week with a wetroom floor that is gonna be a bit of a challenge.

Situation is as follows:

A suspended floor with very little deflection if any.

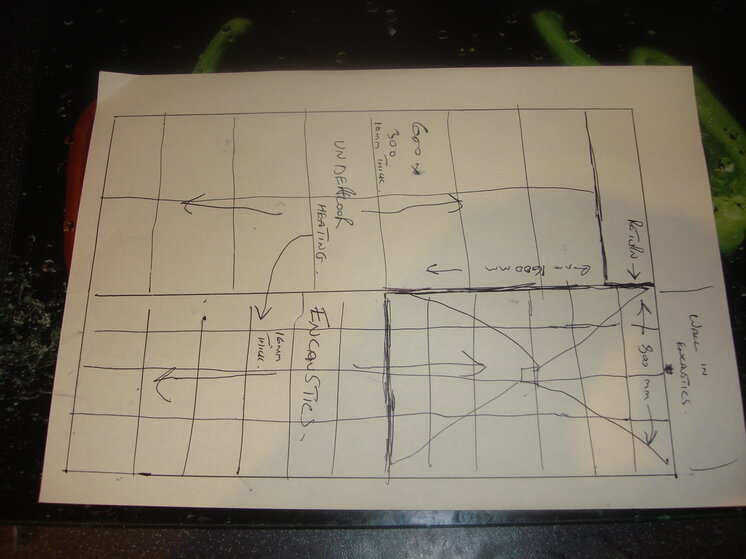

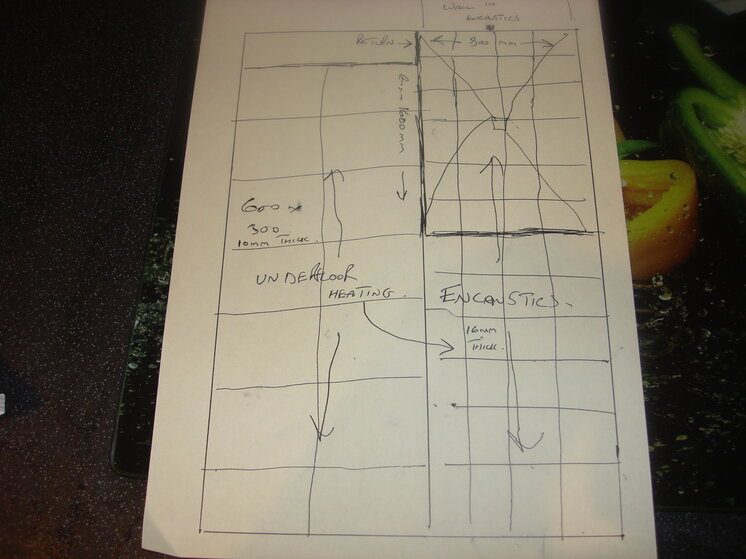

1600x800 former tray going in that is going to be tiled in 16mm thick encaustic cement tiles envelope cut. these are going to run up the wall (on the 800mm side) and run along the floor to the end of the wall following this line. You following so far?

the rest of the floor (about another 6 sqr mtrs is to be tiled in 10mm thick 600x300 porcelain that will have to be finished at the same height as the encaustics. there is underfloor heating going underneath these and the encaustic tiles that are not on the former tray.

My plan was to install tray 32mm-35mm higher then existing floor boards, then tile backer board rest of room in 10mm backer board. then on the porcelain side install another 6mm backer board to allow for thickness difference in tiles. then lay the underfloor heating that will have to step down (chase in to backer board) to go under the encaustics. Then I want to put levelling compound over the wires which by the looks of it will have to be done in 2 stages: first, shutter in the porcelain side (highest side at the moment) and level over wires, then when that's set, go over the wires on the encaustic side using screws to get my exact height as can't afford this to be too high.

I'm not very good with computers otherwise I would try to do some sort of diagram to show what the situation is, maybe someone could advise.

Anyway my biggest concerns are:

1. Getting the heights right so the porcelain and encaustics end up being installed at the same height.

2. With the underfloor heating, different tiles and different thickness of substrates, what are the chances of any potential problems and are there any other possible ways in which you guys would tackle this?

Cheers.

got a job to start next week with a wetroom floor that is gonna be a bit of a challenge.

Situation is as follows:

A suspended floor with very little deflection if any.

1600x800 former tray going in that is going to be tiled in 16mm thick encaustic cement tiles envelope cut. these are going to run up the wall (on the 800mm side) and run along the floor to the end of the wall following this line. You following so far?

the rest of the floor (about another 6 sqr mtrs is to be tiled in 10mm thick 600x300 porcelain that will have to be finished at the same height as the encaustics. there is underfloor heating going underneath these and the encaustic tiles that are not on the former tray.

My plan was to install tray 32mm-35mm higher then existing floor boards, then tile backer board rest of room in 10mm backer board. then on the porcelain side install another 6mm backer board to allow for thickness difference in tiles. then lay the underfloor heating that will have to step down (chase in to backer board) to go under the encaustics. Then I want to put levelling compound over the wires which by the looks of it will have to be done in 2 stages: first, shutter in the porcelain side (highest side at the moment) and level over wires, then when that's set, go over the wires on the encaustic side using screws to get my exact height as can't afford this to be too high.

I'm not very good with computers otherwise I would try to do some sort of diagram to show what the situation is, maybe someone could advise.

Anyway my biggest concerns are:

1. Getting the heights right so the porcelain and encaustics end up being installed at the same height.

2. With the underfloor heating, different tiles and different thickness of substrates, what are the chances of any potential problems and are there any other possible ways in which you guys would tackle this?

Cheers.