R

Russell brown

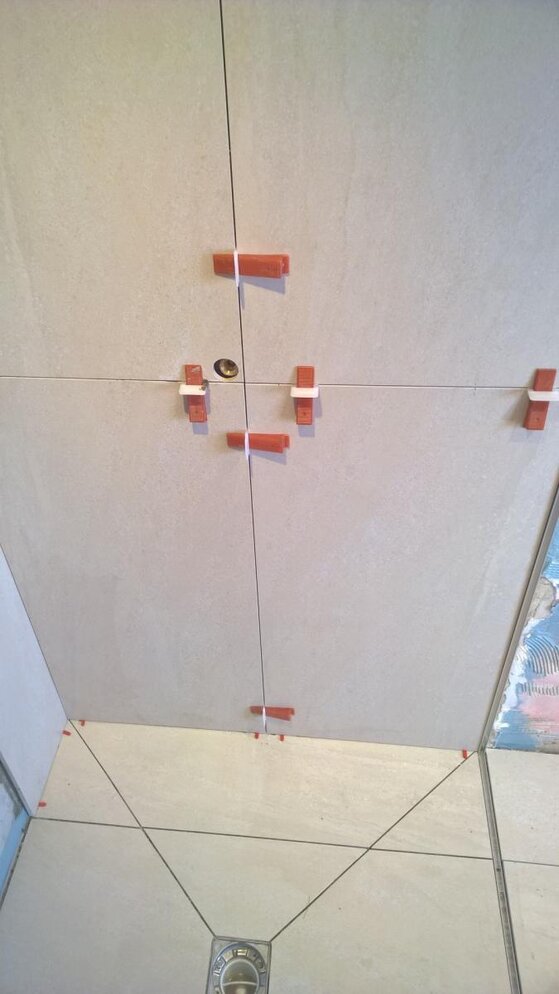

Here's some pics of a en-suite wet room ive just designed, supplied and fitted. First time I've done envelope cuts to a tray but I'm pleased with the result. Had a long chat with 3-fall off here who helped me iron out some concerns on how to do the cuts, top bloke and really appreciate him giving up his time to talk to me and give me advice!. Don't get me wrong ive a long way to go before I get to the standard of some of the people on here but I still enjoy doing different trades to the best of my abilities and always try and push myself, pick up a dewalt d24000 tomorrow:hurray: