O

Old Mod

So as a couple of you may be aware, @Simon Dale his daughter Katrina, and myself are on a project at the Teardrop centre Swanley for Trimline.

Half a dozen rooms in a Florim 1800 x 800 x 12mm, which if you haven’t experienced before is like trying to cut Heather Browns with a pencil scribe!

Even with the use of a high quality large format rail cutter, which can cut to a maximum of 15mm, this stuff is like steel impregnated porcelain.

It’s not my first experience with this material, so I know from old how temperamental and hard this porcelain is.

I managed a 50% success rate with a rail cutter last time and had to grind rest, (cuts on the length are the problem)

With a different rail cutter and techniques I’ve picked up since then I managed to raise it to probably 4 out of 5.

As with all ex large format tho, it’s still not good enough.

Hence the excuse arose to purchase a

Sigma 12E XL 245cm (measures 280cm)

So with the help of Trimline and an order expertly expedited by Derek of @Sigma UK a 3 week made to order machine turned up in just 1 week, thank you all.

Yes it’s ridiculously big, there’s no escaping that, but what a beast of a machine.

Not only is it beautifully made, it’s lightweight (38kgs) relatively easy to use, and

‘does EXACTLY what it says on the tin’

as they say.

It cuts these pieces like a hot knife through butter, it truly does.

It’s changed the whole feel of the project, with dozens of cuts on the length still to be accomplished, instead of there being

‘dread in the air’ it’s all become very stress free.

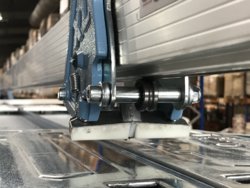

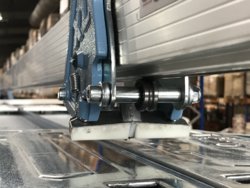

The enormous cutting handle runs on an Aluminium box rail supported by 3 high quality bearings, one top, two underneath.

It glides along the rail with no hint of drift.

The 4 outriggers still suffer the inherent problem (well in my opinion) of being too far off the deck.

I understand why they need to be, but the distance in reality does slightly baffle me.

Yes feeding large slabs between the rail initially feels awkward and is a little nerve racking, however, it does become increasingly easier as you press on.

Not whole lot more to say at this stage, it does feel like a great buy, is it a worthwhile investment?

It’s too early to say for sure.

One thing to bear in mind tho, Simon does intend on renting it out afterwards.

So you know that 1800mm plank job you’ve got coming up that you were dreading!

This is perfect for it. 🙂

Half a dozen rooms in a Florim 1800 x 800 x 12mm, which if you haven’t experienced before is like trying to cut Heather Browns with a pencil scribe!

Even with the use of a high quality large format rail cutter, which can cut to a maximum of 15mm, this stuff is like steel impregnated porcelain.

It’s not my first experience with this material, so I know from old how temperamental and hard this porcelain is.

I managed a 50% success rate with a rail cutter last time and had to grind rest, (cuts on the length are the problem)

With a different rail cutter and techniques I’ve picked up since then I managed to raise it to probably 4 out of 5.

As with all ex large format tho, it’s still not good enough.

Hence the excuse arose to purchase a

Sigma 12E XL 245cm (measures 280cm)

So with the help of Trimline and an order expertly expedited by Derek of @Sigma UK a 3 week made to order machine turned up in just 1 week, thank you all.

Yes it’s ridiculously big, there’s no escaping that, but what a beast of a machine.

Not only is it beautifully made, it’s lightweight (38kgs) relatively easy to use, and

‘does EXACTLY what it says on the tin’

as they say.

It cuts these pieces like a hot knife through butter, it truly does.

It’s changed the whole feel of the project, with dozens of cuts on the length still to be accomplished, instead of there being

‘dread in the air’ it’s all become very stress free.

The enormous cutting handle runs on an Aluminium box rail supported by 3 high quality bearings, one top, two underneath.

It glides along the rail with no hint of drift.

The 4 outriggers still suffer the inherent problem (well in my opinion) of being too far off the deck.

I understand why they need to be, but the distance in reality does slightly baffle me.

Yes feeding large slabs between the rail initially feels awkward and is a little nerve racking, however, it does become increasingly easier as you press on.

Not whole lot more to say at this stage, it does feel like a great buy, is it a worthwhile investment?

It’s too early to say for sure.

One thing to bear in mind tho, Simon does intend on renting it out afterwards.

So you know that 1800mm plank job you’ve got coming up that you were dreading!

This is perfect for it. 🙂