yes, I confirm marc, mine when it was new was fine, a few chips, but now many more

But in Italy it costs € 59 and my work still after 3 or 4 years.

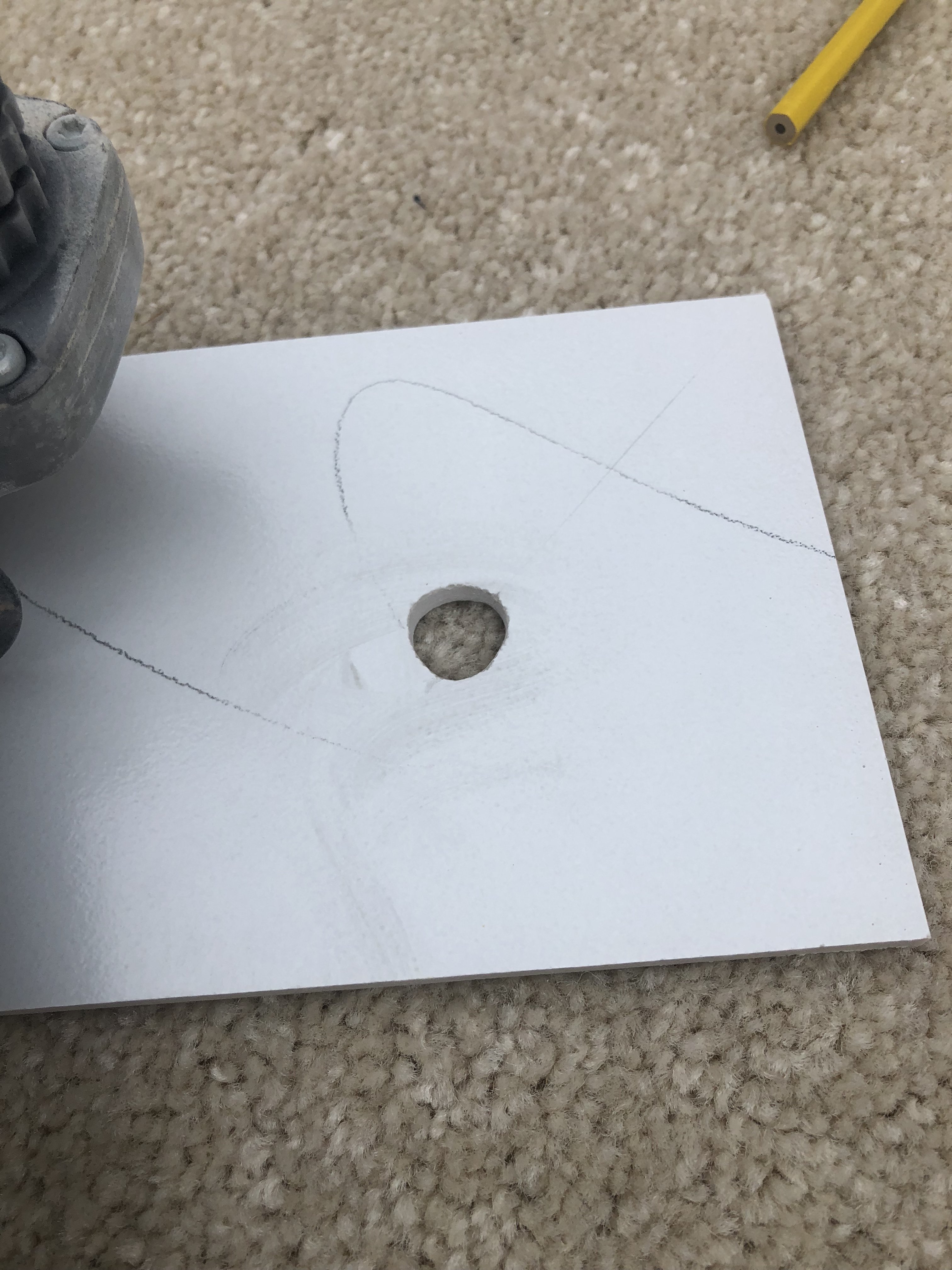

So the solution I tried to have no chips is this.

example of a 30mm hole.

mark the 30mm circle with a pencil, drill with 25mm bits,

use the tapered countersink up to the mark of the pencil.

clean the hole with 20mm of £ 100 without getting to the glaze.

I know it's a long job but it's the only solution I've found.

I guarantee that the conics do not make chips.

I've not seen these before.

This is an interesting conversation. As I explained before, many of these items are designed for stone and repurposed for use in tiling (specifically for porcelain) so it creates some anomalies.

Most VB stone tooling is designed for use on variable speed machines. The speed range give control that isn't available on a regular grinder. So if you have tools that are chipping, try running them slower, you'll find a sweet spot at which the particular grit works better.

Also most of this stuff is designed to be used in stages, but it's something we've never fully embraced in the UK. Why would I buy three + bits if I can make to with one?

I'll use finger bits as an example - with examples of use in granite, which fundamentally is what these things are designed for.

We sell these in three grit levels:-

#30/40 is coarse, it's designed to enlarge a hole or open up an internal radius quickly with little thought for finish or chipping. So you'd use this to remove 3mm to 5mm of material but you'd stop 2mm to 3mm short of your finished line.

#70/80 is medium, you've use this to remove 1mm-2mm of material of after the #30/40. This takes you to within 0.5mm to 1mm of your finished line.

#140/180 - this comes in to play if you're going to see the edge that's been cut, or you're cutting a surface that's going to be polished.

So pay a bit more attention to grit numbers when looking at tools like this. It's quite important.

In reality, #30/40 grit is too coarse for porcelain, it'll be quick but aggressive. It's also the most common used grit on VB holesaws so that's why you get the breakout.

There's nothing to stop you slowing down VB holesaws or using them wet, but a drill driver tends to be a bit slow. A #30/40 VB holesaw will likely produce a cleaner hole cut at 6,000 rpm than it will at 10,000 to 12,000 rpm (standard grinder speed).

#70/80 and #140/180 are probably more useful with porcelain type products