P

PJPro

Hi!

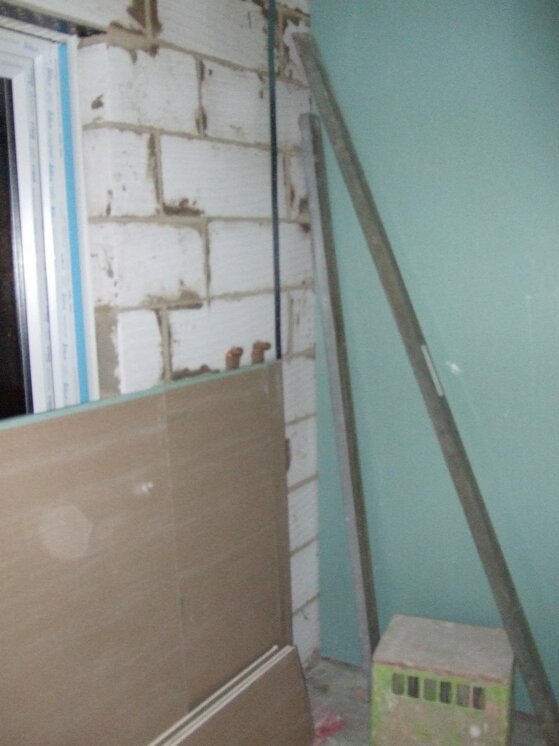

I'm having a new extension built on my house. In fact, I've spent today putting in the CAT6 ethernet network (cables and conduit) and bashing through the old gable wall to join the two lofts. But that's another story.

My wife also ordered the 600x400mm porcelaine floor tiles (10mm thick) from Topps. I've got 90 sq metres coming by the end of the week. I am growing more than a little nervous about the laying of these tiles. I've got the porch, hall, dining room and kitchen floors downstairs to do, as well as the downstairs toliet (walls and floor). I've also got the floor and walls of the upstairs bathroom to do.

I'm going to be under pressure to be quick as the other trades are going to be waiting for me to finish before the 2nd fix carpenty and plumbing goes in.

I'm expecting the upstairs bathroom to be a special challenge. It will contain a quadrant shower enclosure with on wall mixer. The bath, basin and toilet will be placed against a low wet wall of about 1m high, containing all the pipework. The basin and toilet will be hung off this wall using Gerberit installation frames and a hidden cistern. The bath has wall mounted taps.

So. My worries. Well, the main one is making sure I'm doing things right.

The floor will be a moisture proof chipboard, topped with hardybacker. Do I need anything else? Should I also put down a waterproof membrane? How about the joints of the hardybacker? Do I need to use waterproof membrane on the walls/floor of the shower? How about the dry lined walls generally? Should I seal them with something like uPVA before tiling?

I've read with interest some of the banter over Sigma and Rubi dry cutters. The 3B or TX-700-N look good. But are these really going to do the business in the hands of a novice like me or should I be looking to buy a wet saw? I've used a (cheap) dry cutter before, many years ago, without much success.

I'm very worried about cutting the hole for the toilet flush plate. It's a fairly large affair (Gerberit - Kappa). How on earth am I going to cut such a big hole in a porcelaine floor tile? Using a jigsaw? mg_smile:

mg_smile:

Clearly, I've got a lot of holes to drill. Are those Porsadrills really my best bet? I was shocked to see that each bit lasts long enough for two holes before it's ready for the bin. I do have a large drill press.....does this give me other options?

I'm fairly practical and can turn my hand to just about anything. I used to be a skilled labourer in my younger years and I am a qualified (but inexperienced) plumber. I'm hoping with a bit of good advice and encouragement I can pull this off. :hurray:

Grateful for any comments.

I'm having a new extension built on my house. In fact, I've spent today putting in the CAT6 ethernet network (cables and conduit) and bashing through the old gable wall to join the two lofts. But that's another story.

My wife also ordered the 600x400mm porcelaine floor tiles (10mm thick) from Topps. I've got 90 sq metres coming by the end of the week. I am growing more than a little nervous about the laying of these tiles. I've got the porch, hall, dining room and kitchen floors downstairs to do, as well as the downstairs toliet (walls and floor). I've also got the floor and walls of the upstairs bathroom to do.

I'm going to be under pressure to be quick as the other trades are going to be waiting for me to finish before the 2nd fix carpenty and plumbing goes in.

I'm expecting the upstairs bathroom to be a special challenge. It will contain a quadrant shower enclosure with on wall mixer. The bath, basin and toilet will be placed against a low wet wall of about 1m high, containing all the pipework. The basin and toilet will be hung off this wall using Gerberit installation frames and a hidden cistern. The bath has wall mounted taps.

So. My worries. Well, the main one is making sure I'm doing things right.

The floor will be a moisture proof chipboard, topped with hardybacker. Do I need anything else? Should I also put down a waterproof membrane? How about the joints of the hardybacker? Do I need to use waterproof membrane on the walls/floor of the shower? How about the dry lined walls generally? Should I seal them with something like uPVA before tiling?

I've read with interest some of the banter over Sigma and Rubi dry cutters. The 3B or TX-700-N look good. But are these really going to do the business in the hands of a novice like me or should I be looking to buy a wet saw? I've used a (cheap) dry cutter before, many years ago, without much success.

I'm very worried about cutting the hole for the toilet flush plate. It's a fairly large affair (Gerberit - Kappa). How on earth am I going to cut such a big hole in a porcelaine floor tile? Using a jigsaw?

Clearly, I've got a lot of holes to drill. Are those Porsadrills really my best bet? I was shocked to see that each bit lasts long enough for two holes before it's ready for the bin. I do have a large drill press.....does this give me other options?

I'm fairly practical and can turn my hand to just about anything. I used to be a skilled labourer in my younger years and I am a qualified (but inexperienced) plumber. I'm hoping with a bit of good advice and encouragement I can pull this off. :hurray:

Grateful for any comments.