D

DavidJ

I am fixing 12mm Jackoboard (strictly Contract board from CTD) to a studwall with 600mm studs. The board is 2400x600mm and I am laying the long edge horizontally along several studs.

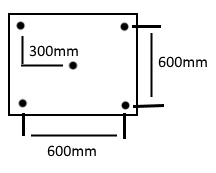

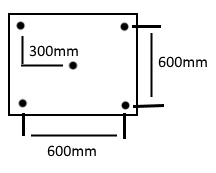

I have fixed a screw into each stud along the horizontal edges (600mm centres) and also have fixed noggins 300mm up from the edge and attached a screw into this at 300mm offset to the edge screws. Please see that attachment for the stud pattern per 600mm square.

While the centre of the board is perfectly solid, if I grab the edge in the middle between two studs it is quite flexible which doesn't seem right.

The instructions I have found online seem to require a minimum of 5 screws per 1 square metre. The pattern I have used definitely exceeds this.

Can someone who has used these boards on a stud wall share what pattern of fixings they used?

I have fixed a screw into each stud along the horizontal edges (600mm centres) and also have fixed noggins 300mm up from the edge and attached a screw into this at 300mm offset to the edge screws. Please see that attachment for the stud pattern per 600mm square.

While the centre of the board is perfectly solid, if I grab the edge in the middle between two studs it is quite flexible which doesn't seem right.

The instructions I have found online seem to require a minimum of 5 screws per 1 square metre. The pattern I have used definitely exceeds this.

Can someone who has used these boards on a stud wall share what pattern of fixings they used?

Last edited by a moderator: